Loading... Please wait...

Loading... Please wait...12V VR6 Serpentine Belt Replacement / Tensioner Bearing Lubrication

Please give credit where credit is due! These DIY's were completed ENTIRELY by Gary Thompson, Ph.D. Please make sure to say thanks to Gary, and if you ever see him at a bar, buy em a beer. These DIY's are more complete than anything Bentley has ever written!!

PLEASE ALSO NOTE : GARY HAS ABSOLUTELY NO AFFILIATION WITH GRUVENPARTS.COM !!! DO NOT CONTACT HIM DIRECTLY CONCERNING ANY PARTS SOLD ON THIS WEBSITE. HE HAS MERELY GIVEN PERMISSION FOR ME TO MIRROR HIS GREAT WRITE UPS FOR YOUR BENEFIT.

Please also DO NOT COPY AND PASTE THESE DIY's to another website without first getting approval from either GruvenParts.com or Gary!! He worked hard on all this stuff so you dont waste time trying to learn it on your own. He is VERY generous, but he deserves your asking him before you start posting this stuff on your own website!

Please also note that these DIY's are to be used for REFERENCE ONLY. While Gary has probably forgotten more about VW's than the rest of us will ever learn in our lifetime, neither he nor me are responsible if you screw something up. Bottom line - dont touch your car if you dont know what you are doing.

A billet version of the tensioner pulley can be bought from www.GruvenParts.com.

REMOVING A VR6 SERPENTINE BELT TENSIONER AND LUBRICATING THE TENSIONER PULLEY BEARING

The following outlines the procedure for removing the serpentine belt tensioner from a VR6 engine and lubricating the tensioner pulley bearing. It is common for the bearing in the pulley to dry out, causing the bearing to become very noisy when the engine is running and eventually, to fail. The lubrication of the bearing as preventative maintenance or at the first sign of noise can significantly extend the lifetime of the tensioner pulley. Since VW does not sell the pulley separately, lubricating the bearing with a few cents worth of grease before bearing failure can prevent you from having to (1) purchase a whole new OEM tensioner unit for $100-200 (depending on where you buy it from), (2) purchase an aftermarket pulley (such as the Adrenalin version) for $50-100 or (3) buying a new bearing and spending the time and/or $$$ to install it in the existing pulley.

The procedure below was based on a '99.5 MKIV Jetta GLS 12v VR6. The steps for accessing the tensioner unit may/will be different on other model VR6s (for example, I believe the airbox must be removed on a MKIII VR6), but the procedure for disassembling the tensioner and lubricating the pulley bearing should be the same.

Please do these procedures at your own risk and be ready to make small adjustments while doing them. Also, please be observant while removing parts so that they back together correctly.

The procedure below is very simple and should take around a half an hour to perform.

The tools/parts needed to perform the procedures are:

1) T30 Torx driver

2) M8x**x1.25 pitch bolt, where ** is the length in mm (available at Home Depot, Lowe's or other hardware stores). I have not specified a length since it varies depending on the model year/version VR6 you have.

2) 13mm socket or wrench

3) 15mm socket or wrench

4) Small screwdriver

5) High-temp wheel bearing grease or other suitable lubricant

6) 6mm hex wrench or socket (if the bolts on your VR removed in Step 5 are this type)

____________________________________________________________________

REMOVING THE SERPENTINE BELT TENSIONER

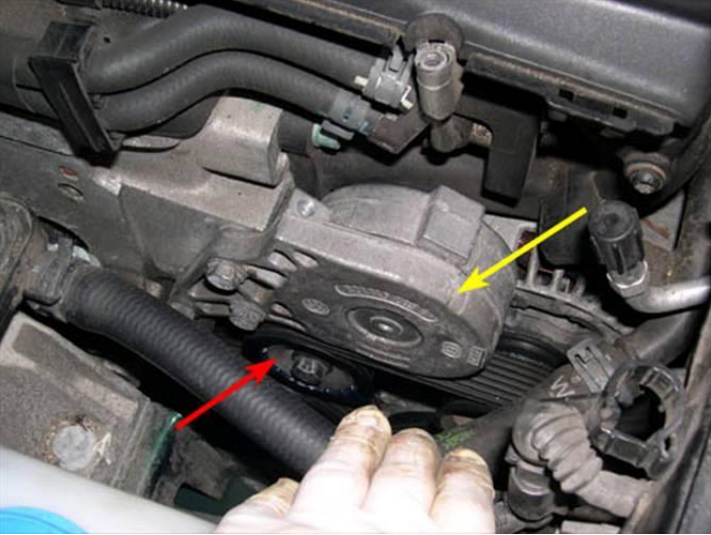

1. The serpentine belt tensioner is located on the passenger's side of the engine, as indicated by the yellow arrow in the picture below.

2. Remove the long cover piece on the passenger's side of the engine to reveal the tensioner. To do this, remove the two (2) T30 Torx screws (indicated by the yellow arrows in the picture below) and carefully pull upward on the cover piece.

3. The serpentine belt tensioner is indicted by the yellow arrow in the picture below. The tensioner pulley which applies force to the serpentine belt is indicated by the red arrow.

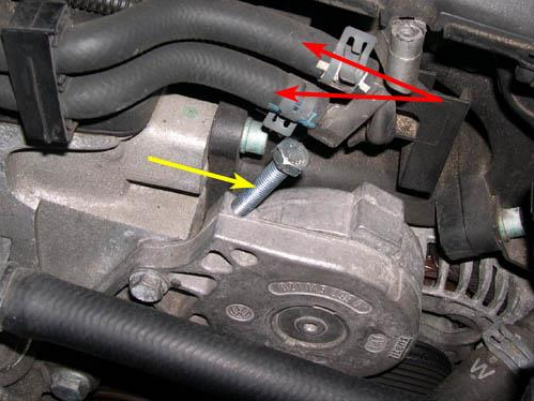

4. To remove the tension from the serpentine belt, thread a M8x**x1.25 pitch bolt into the threaded hole in the top of the tensioner unit (as indicated by the yellow arrow in the picture below) and turn using a 13mm socket or wrench until the serpentine belt is loose. ** is the length of the bolt in mm and will depend on the model year/version VR6 you have. Basically, you need a bolt that is long enough to fully remove the belt tension before the bolt head threads in completely, but is short enough to not interfere with the fuel lines overhead (red arrows in picture below). On my '99.5 VR6 a 60mm bolt works perfectly, however, on my friend's '00 VR6 the same bolt is too long. I recommend that you purchase a few bolts with different lengths and return the ones that don't work.

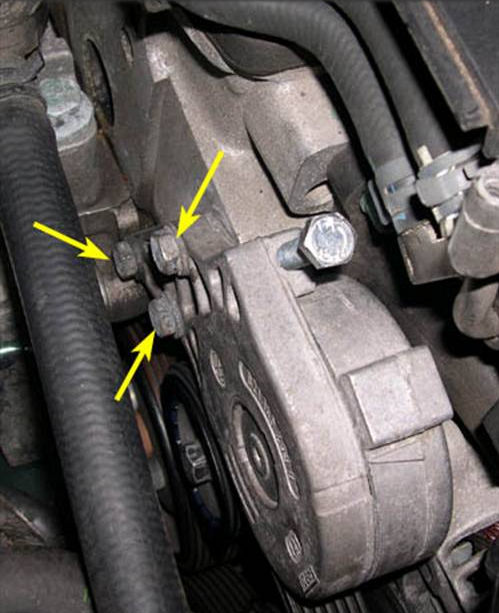

5. Once the belt tension has been removed, remove the tensioner unit from the engine by removing the three (3) 13mm bolts indicated by the yellow arrows in the picture below (Note: On some cars, these bolts will be 6mm hex instead). When the three bolts are out, slide the serpentine belt towards the passenger's side of the car and off of the tensioner pulley. You should now be able to remove the tensioner unit from the engine.

NOTE: If you do not plan on lubricating the pulley bearing and reinstalling the tensioner back onto the engine right away, I recommend that you remove the M8 tension-release bolt to release the extra tension from the spring inside the tensioner. While not likely, it's possible that the spring may be damaged or deformed if it sits for too long in an over-tensioned state. If you do remove the tension, make sure to thread the M8 bolt back into the tensioner and reapply tension to the spring before reinstalling the tensioner onto the engine. If you don't, you will not be able to get the serpentine belt back onto the tensioner pulley.

LUBRICATING THE TENSIONER PULLEY BEARING

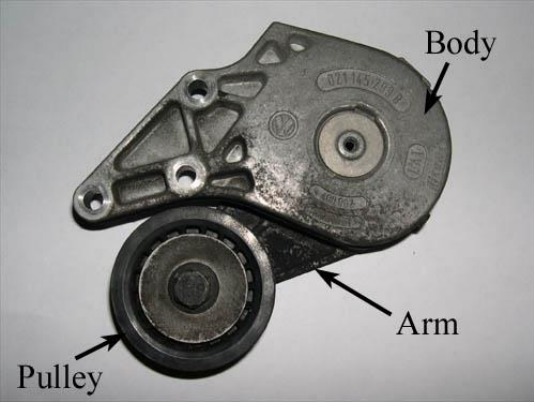

6. The picture below shows the three main parts of the tensioner unit - the main body, the spring-loaded arm and the idler pulley.

7. Remove the pulley from the tensioner arm by removing the 15mm bolt indicated by the yellow arrow in the picture below (shows the bolt partly removed). NOTE: THE BOLT IS REVERSE THREAD. TURN IT CLOCKWISE TO REMOVE!!!

8. The picture below shows the pulley removed from the tensioner unit. Note that there is a pulley guard (top center of picture) that is used between the bolt and pulley.

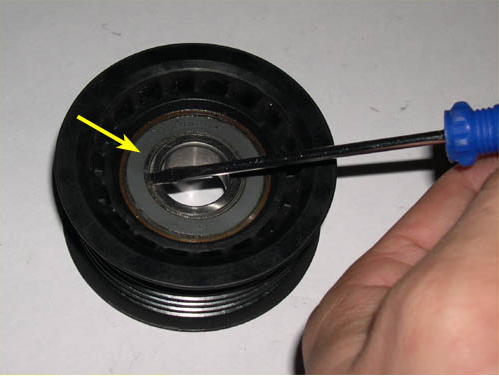

9. Use a small screwdriver to remove the seals from each side of the pulley bearing, as shown in the picture below. To do this, insert the screwdriver between the seal and inner race and VERY CAREFULLY pry the seal upward. Make sure you do not damage the rubber coating on the seal or it may not stay in place when reinstalled.

10. The picture below shows the tensioner pulley with both bearing seals removed.

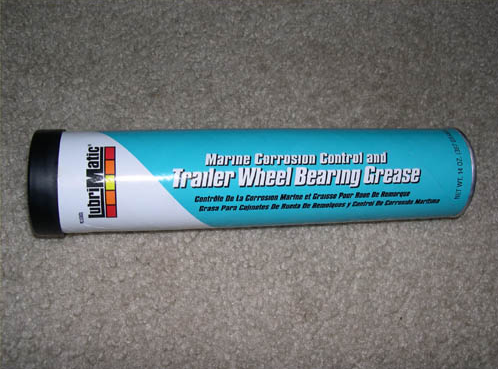

11. Pack each side of the bearing with some high temp. wheel bearing grease or another suitable lubricant, as shown in the picture below. You can also add a drop or two of oil to thin out the grease if it's very thick.

12. The grease that I used is shown in the picture below. I purchased it at either Home Depot or Lowe's (can't remember) for around $3-4.

13. Once the bearing has been packed with grease, carefully reinstall the bearing seals. MAKE SURE THAT THE SEALS ARE INSTALLED FULLY OR THEY WILL WORK THEMSELVES LOOSE AND WEAR AGAINST THE PULLEY GUARD OR TENSIONER ARM WHILE THE PULLEY SPINS.

14. Reinstall the pulley onto the tensioner unit and then reinstall the tensioner unit back onto the engine by following steps 2-8 in reverse. Remember that the pulley bolt is REVERSE THREAD - turn it counter-clockwise to tighten. If you have a torque wrench, the torque spec for the tensioner-to-engine bolts are 18 ft-lbs. I could not find the torque spec for the pulley-to-tensioner bolt, but 30 ft-lbs should be appropriate.

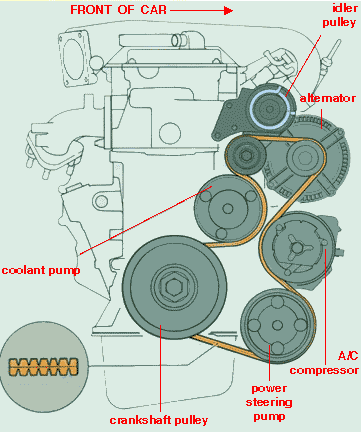

15. After reapplying tension to the serpentine belt and BEFORE starting the engine, check to see that the belt is properly positioned on ALL of the pulleys that it contacts.

Let me know if you have any questions.

EDIT (3/5/04): For those interested in replacing the serpentine belt, the illustration below shows how to route the belt around the various accessory pulleys.

Most Popular

-

1

-

2

-

3

-

4

-

5